Where else in the world can you stand on the deck of your boat overlooking a spectacular vista of the surrounding area … until you glance off the stern where it looks like you’re on the very edge of the world with a gargantuan 65′ drop, straight down!

It takes just over 2 minutes from when the lock chamber begins to lift until your boat is at the tippy top – the video above is in 2X motion so it takes less than a minute.

- Peterborough Lift Lock on the Trent Severn Waterway, Ontario Canada is not only the highest lift lock in the world but it was completed in 1904 … that’s over 114 years ago… Lock 21 raises boats 65 feet – SIX STORIES!!! – an amazing engineering feat from back in the day when the average lock raised a boat 7 feet.

- We were SO lucky to meet Rob and Glenda on Monterey, now Gold Loopers, from Peterborough, Ontario. We met them at Cape May, New Jersey. Rob photographed Looper boats at the Peterborough Lift Lock and provided all these AMAZING pictures that we could never have gotten otherwise. SPECIAL THANKS to Rob for documenting Optimystique’s ride! 🙂

-

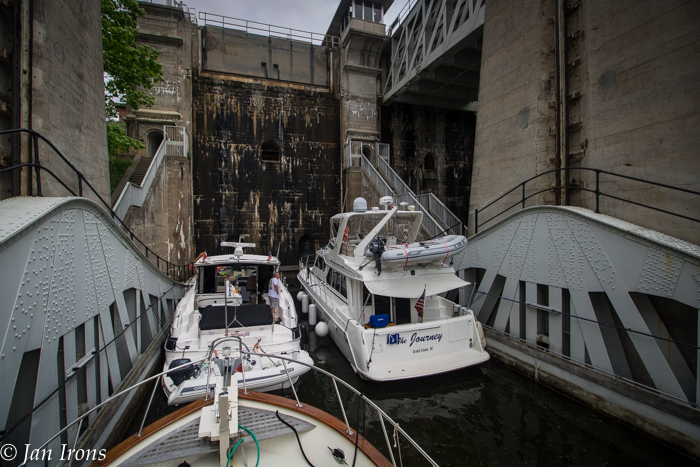

Optimystique going into the lower chamber behind several other boats – you can see the upper chamber on the upper right. Being in the back is good – we get to see over the back … 65′ straight down! On top of the world! - There are two HUGE chambers in the lock – essentially giant (and I do mean giant) bathtubs. The chambers counterbalance each other – we drove the boat in the one at water level and the other was WAY up high. Then they slowly fill the upper chamber with enough water to force the “bathtub” that we floated in to ascend, straight up, until it reaches the upper river height, then opens to release the boats.

- The lock uses no external power to raise the boats, it’s entirely gravity driven on a counterweight principle.

- Concrete, concrete and more concrete! In the early 1900s, concrete as a construction material was in its infancy and reinforcement with steel was viewed as skeptical, thus this lock was constructed with over 26,000 cubic yards of concrete without any reinforcement and it still stands and operates over 100 years later.

- In addition to the concrete, 1400 tons of metal were used in the construction of the lock.

- The final project included many engineering firsts. It was the first lock to be built out of concrete, and at the time was the largest structure ever built in the world with unreinforced concrete.

- Over 5,000 boats a year lock through the Peterborough lift lock, which doesn’t seem like alot until you consider that much of the year it’s frozen ice, only open from mid-May to early October … 4-5 months-ish….

- And, of course, politics played a part in the building of the lift lock. It was an election year and in order to generate local support the lift lock project was sped up. In 1896 construction was approved and contractors signed prior to any working drawings being finalized. The party in power lost the election, and, the architect, Richard Rogers, concerned about his ties to the former administration, released only part of the working drawings in stages. He was allowed to remain on the job as the main designer.

- The lift lock officially opened to the public to a crowd of thousands on July 9,1904.

- The original steelwork is still used today, modified by zinc refinishing and welding on the boat chambers. (New aluminum gates were added during the mid-60s.)

Looking for a more technical explanation… here you go! Courtesy of Wikipedia….

“No external power is needed: the lift lock functions by gravity alone using the counterweight principle. One caisson always ascends and the other always descends during each locking cycle. When one caisson reaches the top position, it stops 12 inches (30 cm) below the water level of the upper reach, and the control valve is closed; ultrasonic sensors are used to help determine the differential. The upper reach and top caisson gates open, and water flows into the top caisson until the level equalizes. The weight of the extra foot of water is 144 short tons (131 t), making the total weight of the upper caisson 1,844 short tons (1,673 t).

Any vessels that just ascended in the top caisson exit into the upper reach, and any new vessels making a transit of the lock then enter the bottom or top caisson from the lower or upper reach respectively. Once the vessels are secured, all gates are closed and the crossover valve in the connecting pipe between the ram shafts is opened.

Since the upper caisson weighs more than the lower caisson (1,844 vs 1,700 tons), it pushes down on its ram, forcing out water from its shaft via the connecting pipe into the shaft of the bottom caisson. The force pushes up on the bottom caisson’s ram, raising the caisson up to the top position. When the gate of the newly descended top caisson and lower reach gates open at the bottom, the extra foot of water flows out and equalizes with the water level in the lower reach of the canal, and any descended vessels exit, allowing the cycle to start over again.”

All I can say is, Peterborough, Lock 21, was an amazing experience & one that we can’t wait to repeat on Lock 36 — the 2nd Lift Lock in the Trent Severn Waterway, Kirkfield. Kirkfield is the first descending lock… until Kirkfield, we’ll continue going up, up, up! Then we’ll descend until reaching Georgian Bay in the northern reaches of Lake Huron.

Do you know more fun facts about the Peterborough Lift Lock? Please leave a comment and share! Cheers! Jan

So cool! We’ve been to the Peterborough Lift Lock but have never locked through….yet! An amazing piece of engineering. Enjoying your blog, Carleen

What a fantastic trip – thanks for letting us ride along!